Manufacturing

Highly automated, commercial scale operation in full compliance of worldwide GMP.

Raw material control

We have complied strict qualification measures on every raw materials. Each batch of raw material was inspected to guarantee the quality consistency.

1. Vendor Management

Qualification protocol is well implemented, provided samples should pass the QC inspection and stability test.

2. Inspection-Incoming Material

When raw materials delivered to our plant, a series of receiving procedures are addressed to ensure the quality.

3. Sampling Test

According to the GMP sampling program, a sufficient amount of sample should be taken batch by batch for the quality control test.

4. Release and Storage

After passing the material inspection, released materials are stored in the controlled area of the warehouse.

Manufacturing process

Vetnostrum has several dedicated production lines for different product categories, HVAC systems, and HEPA-filtered facilities to prevent cross-contamination.

-

QA / QC

- Incoming/IPC/Release test

- Inspection batch by batch

- Quality management

-

Production

- SAP & GMP implemented

- Pneumatic conveyor system & automatic equipments

- Multiple production lines

- Automation & EHS management

- Supply chain management

- Just-in-time inventory

- Rolling forecast system

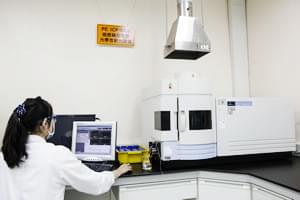

Inspection Instrument

Vetnostrum has built a laboratory with various equipment, including Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), Ultra Performance Liquid Chromatography (UPLC), High Performance Liquid Chromatography (HPLC), Gas Chromatography (GC), etc., to ensure that raw materials and finished products all comply with regulations.

Storage Management

The sampling test is done to assure finished products within specifications consistently. The storage temperature is controlled below 27 ℃. The storage area passed the GMP inspection to ensure the effectiveness of raw materials and finished products.

27°C

Full-time thermal control

GMP

GMP certified